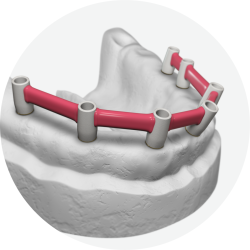

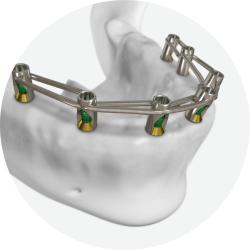

Screw-retained restorations

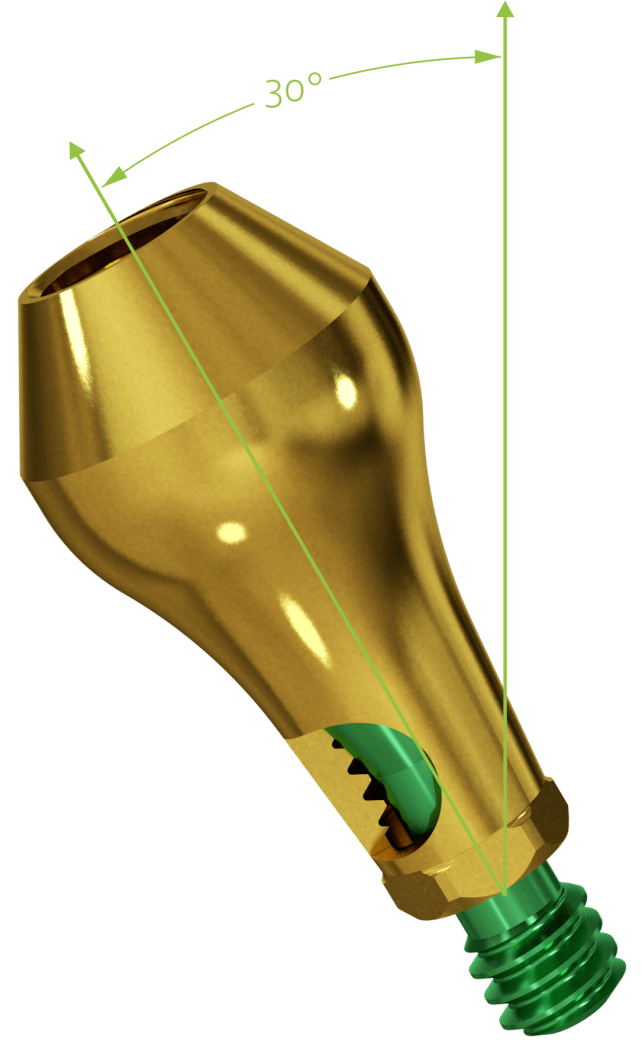

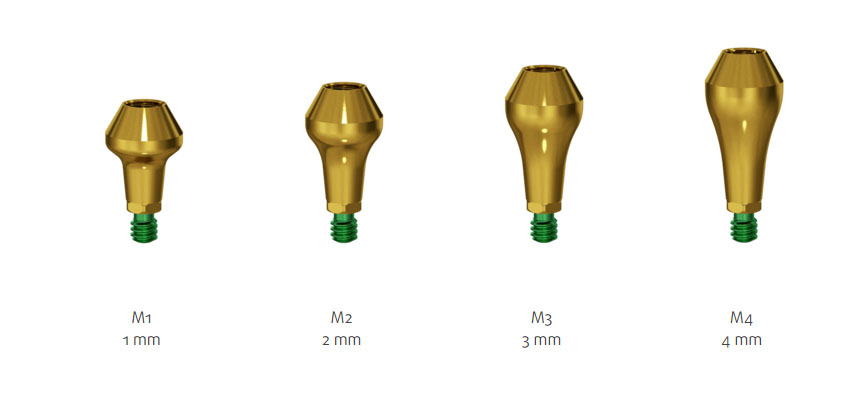

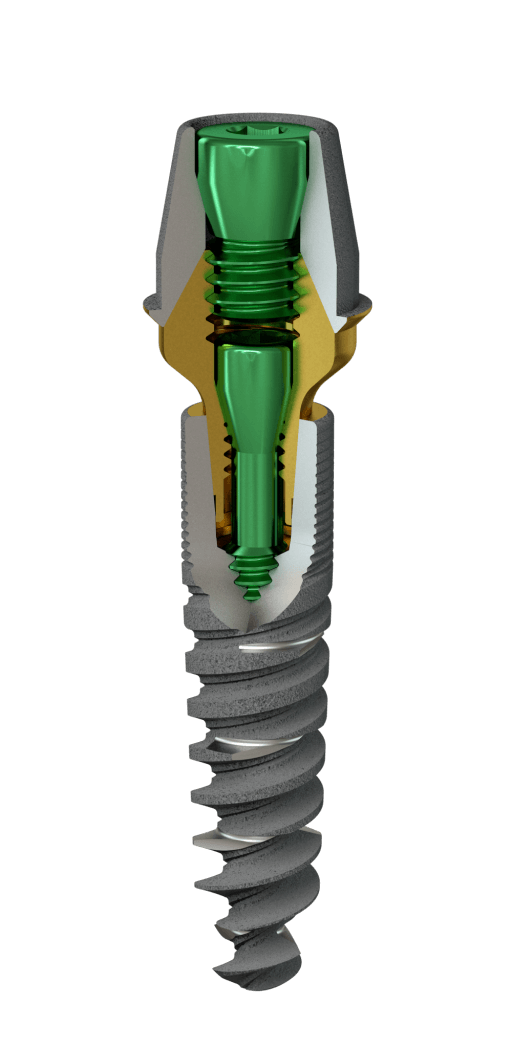

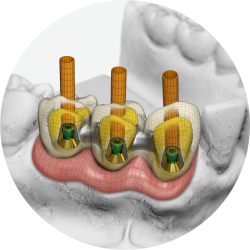

Are used for prostheses supported by two or more dental implants with screw-retained fixation. Platform cone of 60° allows us to produce prostheses supported by implants with non-compliant implant axes of up to 30 °. Two-component multi-unit abutment consists of a body and a fixing screw. Available in four versions with the height of a gingival area from 1 to 4 mm. Using multi-unit abutments on model is unacceptable.

Surface

Multi-unit abutments is made of Ti6Al4V, polished and anodized in gold color, allowing more aesthetics is achieved in the soft tissue.

Internal thread

Easy removal of multi-unite by a removable key (SR), eliminating unwanted force on implant in case of extra fixation.

Conical conection

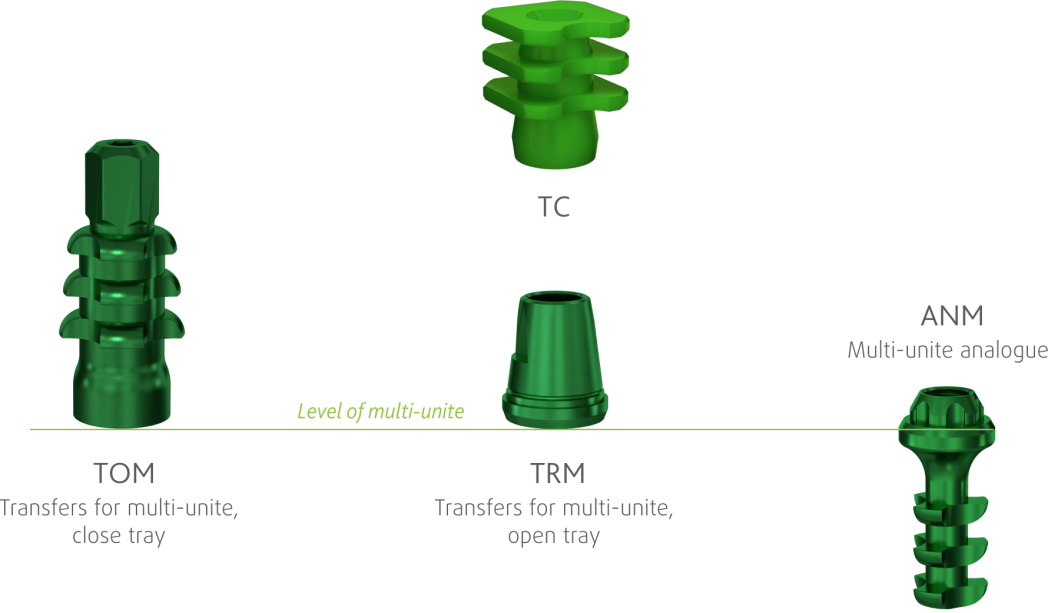

Together with hex allows you to securely lock abutment, creating a tight connection with the implant and preventing unwanted micromotion. In process of working with multi-unite abutments follow the rules: multi-unite must be installed once to implant and to not be remove till delivery of finished prosthesis. To obtain impression, use transfers for multi-unite abutments (TOM) and for models use analogs of multi-unite abutments (ANM).

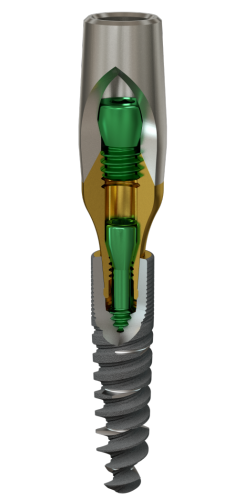

Titanium base for multi-units is designed for the manufacture of high-precision individual restorations with hybrid screw-retained prostheses fixation. Designed towards the latest requirements of digital dentistry. Base design together with a particular milling protocol can significantly reduce the time for crowns manufacture.Supplied with an individually packed laboratory fixing screw (SL8 – red) and a clinical screw (S8 – green).

Surface

Sandblasted base with gingival area and implant interface anodized in gold color allowing to achieve better aesthetic in soft tissues. Titanium base is made of Ti6Al4V.

Interface

Accurate and reliable multi-unit base connection due to conical screw.

PCOM

Scan-post for PCOM titanium base

Designed in accordance with the requirements of the latest 3D scanners. Made of Ti6Al4V, the surface is conditioned to a matt structure for accurate results and longer life.

PCOM

Titanium base for multi-unite abutment

Designed for the manufacture of high-precision restorations with screw-retained prostheses fixation. Supplied with an individually packed laboratory fixing screw (SL8 – red) and clinical screw (S8 – green).

Abutments for intraoral welding are developed in accordance with wall thickness requirements and are used for multiple restorations with screw-retained prostheses and denture reinforcement by contact welding in the mouth or laboratory model. The surface is polished, Ti6Al4V material.

Interface

Accurate and reliable multi-unit base connection due to conical screw.

AM

Titanium base for multi-unite abutment

Designed in accordance with the requirements of the latest 3D scanners. Made of Ti6Al4V, the surface is conditioned to a matt structure for accurate results and longer life.

ABMU

Burnout abutment

Manufactured on high-precision CNC-machines for accurate casting with fixation on multi-unit abutments. POM-C material. Requires special reamer after casting.